HEAT SEALERS

HEAT SEALERS

Efficient packaging

The use of quality packaging, as well as the execution of a correct packaging, play a fundamental role in the reprocessing sequence of medical devices, which can only be considered “STERILE” when their aseptic presentation and, therefore, the preservation of their sterility, is guaranteed until the moment of use with the patient.

The international standard for the packaging of medical devices ISO 11607-2 and the new ISO 16775 guidelines describe how this process should be validated by assessing and determining the optimum sealing temperature of the material to be packaged. At this temperature, the process must generate an optimal seal, strong enough to guarantee asepsis and which, at the same time, allows the material to be peelable without generating cracks or residues.

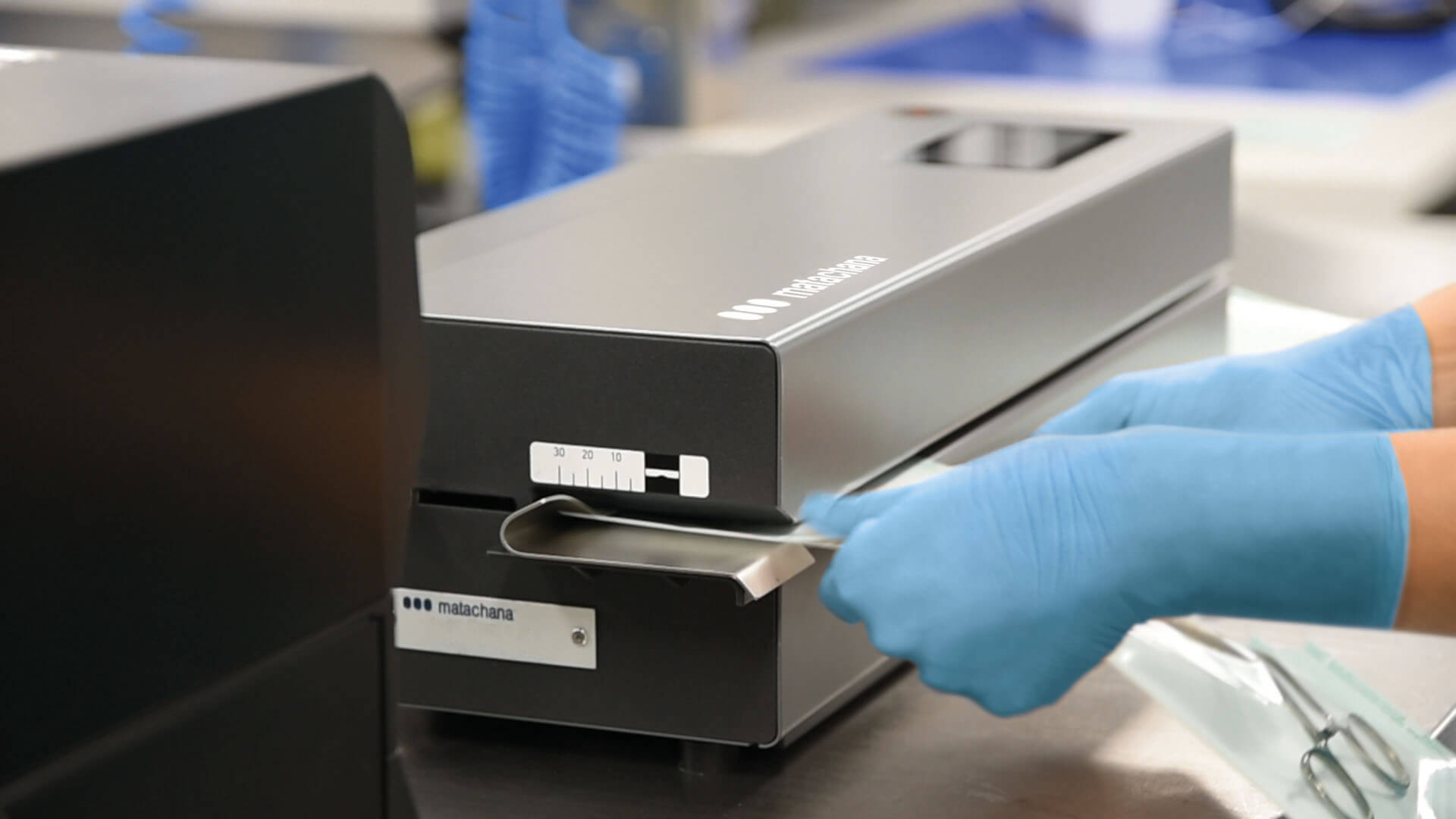

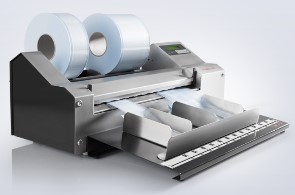

For this purpose, professional heat sealing equipment for the sealing of bags and reels (preformed Sterile Barrier Systems, SBS) is essential.

MATACHANA HEAT SEALERS

MATACHANA has a range of sealing devices whose processes can be validated according to the new standards. The models marked “V” have an integrated function for monitoring the three key process parameters: temperature, contact pressure and sealing time.

MATACHANA sealers guarantee efficient and reproducible packaging, even with large instrument volumes.

Sealing equipment and accessories for the packaging of sealable pouches and reels in healthcare facilities:

Continuous band sealers

Impulse bar sealers

Bag sealing and cutting machines